AeroAuto Systems

Achieved 3x Faster Decisions and 38% Less Downtime with ERPNext Implementation

97%

Operational Visibility

3x

Faster Decisions

80%

Less Manual Errors

50%

Cut in Rework Costs

A USA-based precision equipment manufacturer serving the automotive and aerospace sectors sought to modernize its multi-plant operations. Their legacy ERP system created silos and slowed down decision-making. Our team implemented ERPNext to unify production, boost visibility, and enable a truly data-driven manufacturing ecosystem.

Country

USA

Duration

4 months

Industry

Manufacturing

Services

ERPNext Consulting Discovery Process Mapping Custom Module Development Workflow Automation Data Migration & Integration Optimization and Support

Technologies

MariaDB Python MQTT Webhooks Sentry

Problem Statement

Problem Statement

The client’s existing ERP and manual processes created bottlenecks in production planning and material tracking. With no real-time visibility into work orders, quality inspections, or machine utilization, downtime was high, and on-time delivery rates were dropping. Leadership needed a single, transparent system to unify all manufacturing operations, from procurement to dispatch.

Challenges

Challenges

- Fragmented systems for inventory, production, and accounting created redundant data entry.

- Lack of predictive analytics and MRP automation delayed planning decisions.

- Quality checks were handled manually, leading to high error margins.

- Difficulty in maintaining traceability across multiple production lines.

Solution

Solution

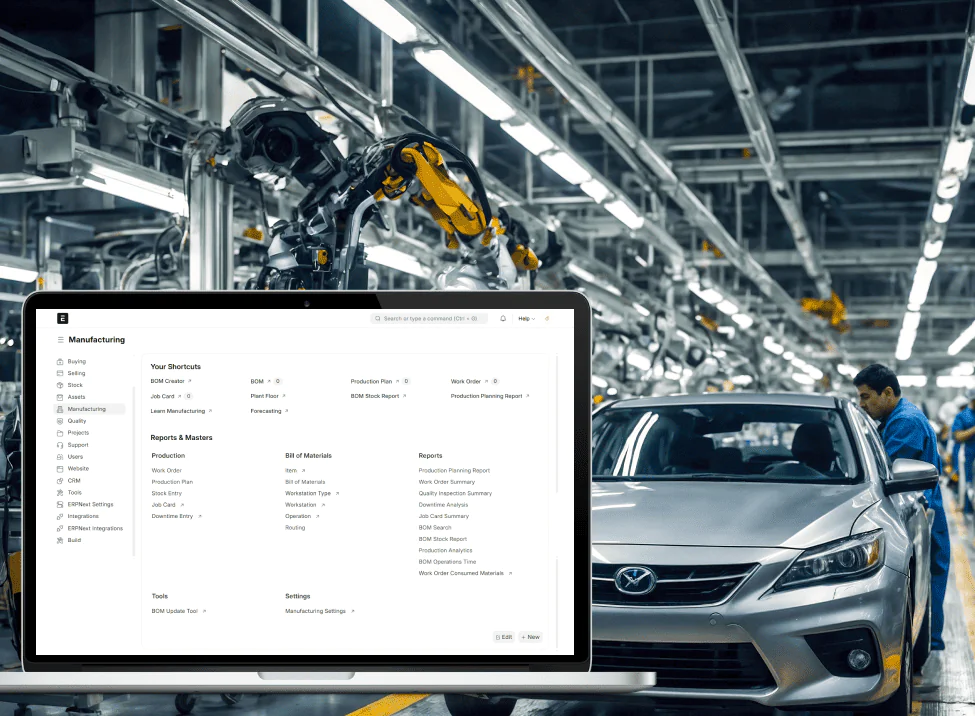

- Our ERPNext experts initiated the engagement with a process discovery workshop involving operations, finance, and production managers.

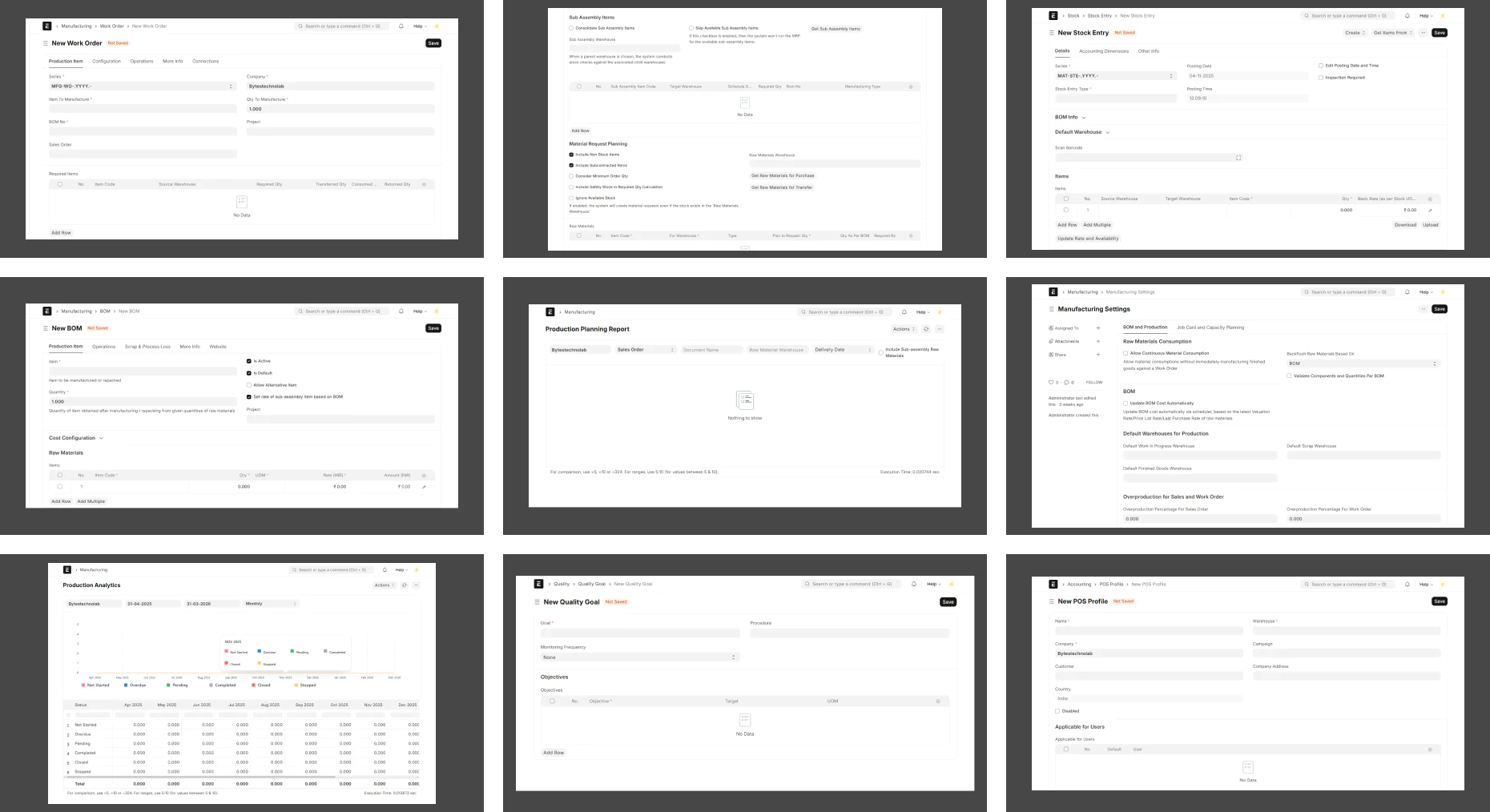

- We mapped their complete workflow, from raw material procurement to finished goods delivery, and designed custom modules for production planning, BOM management, and quality inspections within ERPNext.

- Integration with IoT-based machine sensors allowed automated runtime data logging, while MRP automation optimized purchase orders and material movement. Dashboards were built for plant heads and executives to track performance, downtime, and cost metrics in real-time.

- All data was migrated to ERPNext with zero downtime, supported by a secure role-based access model to maintain compliance with ISO and client-specific manufacturing standards.

Result

Result

Our ERPNext implementation services resulted in immediate and measurable improvements in operational control, efficiency, and accuracy.

- 38% reduction in production downtime through real-time machine utilization tracking.

- 45% improvement in inventory accuracy via automated material and stock reconciliation.

- 25% faster production cycle with dynamic work order scheduling.

- 60% better visibility across departments, improving coordination between planning, finance, and operations.

Unified manufacturing, procurement, and accounting processes into a single ERP system.

Deployed real-time dashboards for executives to make faster operational decisions.