AgroBuild Tech

Enhanced Manufacturing Efficiency by 42% with ERPNext-Driven Planning and Forecasting Solutions

98%

Accurate Forecasting

2.5x

Faster Material Planning

40%

More SCM Visibility

99%

On-Time Orders

A leading U.S. industrial machinery manufacturer faced unpredictable demand, delayed deliveries, and mounting costs due to poor forecasting and visibility. Bytes Technolab implemented ERPNext to unify forecasting, procurement, and production, driving digital transformation and restoring operational control.

Country

USA

Duration

5 months

Industry

Manufacturing

Services

ERPNext Consulting ERPNext Implementation Process Automation Integrations Data Migration Ongoing Support

Technologies

Node.js Frappe Avalara Snowflake Docker

Problem Statement

Problem Statement

The client’s legacy ERP could not accurately track sales trends, supplier timelines, or seasonal demand variations. Departments worked in silos, sales data wasn’t synced with production, and raw material orders were often delayed or duplicated. The company faced excess stock during slow months and severe shortages during peak demand. It was disrupting delivery commitments and hurting customer satisfaction.

They needed a robust ERPNext implementation to integrate real-time forecasting, automate workflows, and bring transparency across every stage of the production cycle.

Challenges

Challenges

- Lack of integration between sales, inventory, and production planning systems.

- Manual forecasting methods prone to errors and inconsistencies.

- Inefficient procurement planning resulting in high carrying costs.

- Absence of actionable insights for capacity planning and vendor performance.

Solution

Solution

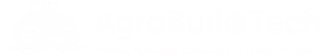

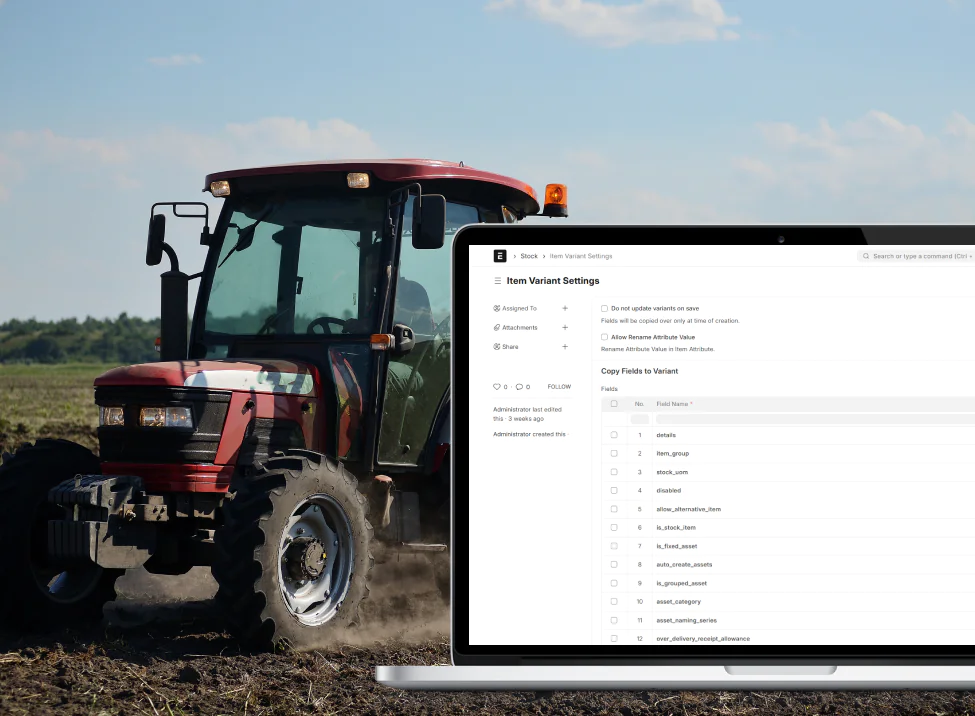

- Initial ERPNext consultation services helped our team to understand needs and design a centralized ERPNext framework. It was built to integrate sales orders, demand forecasting, material requirements planning (MRP), and vendor management.

- Custom modules were added to connect ERPNext with IoT-enabled production machinery, ensuring real-time tracking of work orders and resource utilization.

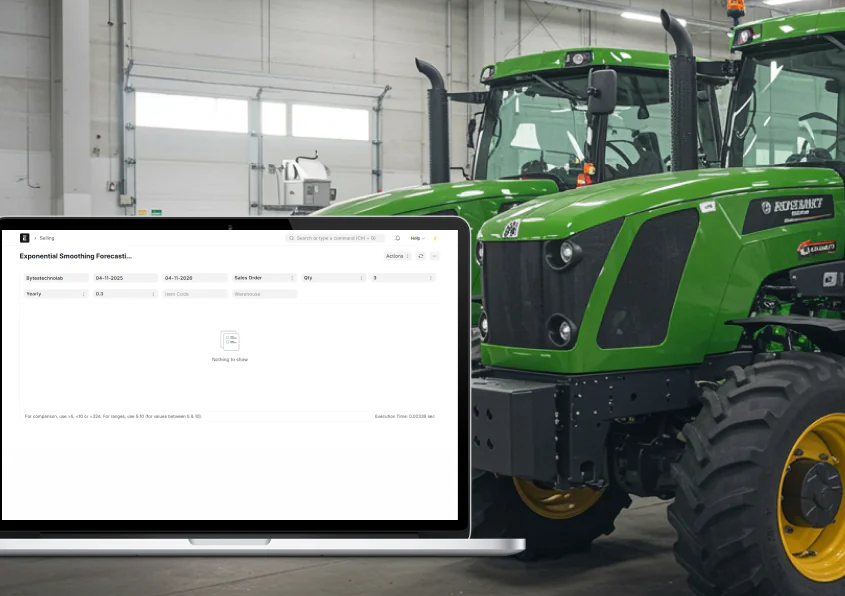

- Predictive analytics capabilities were embedded within ERPNext to forecast material requirements and optimize production schedules.

- Integration with third-party logistics and supplier portals streamlined procurement, while automated alerts minimized overstocking and production halts. The entire solution was deployed on a secure cloud infrastructure with role-based access for scalability and compliance.

Result

Result

With predictive forecasting and integrated planning tools, the company achieved faster turnaround, reduced costs, and stronger supply chain resilience.

- 42% improvement in production planning accuracy through real-time forecasting.

- 30% reduction in raw material wastage with optimized procurement.

- 55% faster response to demand fluctuations.

- 3x improvement in collaboration across departments.

Our experts integrated sales, inventory, and production modules into one centralized ERPNext platform.

Enabled real-time demand forecasting using historical and live sales data.